Let’s be honest: The world of supply chain technology is noisy.

Open LinkedIn on any given Tuesday, and you’re bombarded with buzzwords. Everyone is telling you that you need AI, Blockchain, Digital Twins, or Autonomous Drones right now or your business is doomed.

If you are a growing business owner or an operations manager, this is overwhelming. You aren't trying to colonize Mars; you’re just trying to get a pallet of goods from Point A to Point B without losing money or your sanity.

Here is the reality that software vendors won't tell you: Technology is not a silver bullet. It is a ladder. You don't need a Ferrari to drive to the grocery store, and you don't need a million-dollar SAP implementation if you're shipping 50 orders a day.

Let’s cut through the noise and look at what a practical, scalable tech stack looks like, from the startup phase to the big leagues.

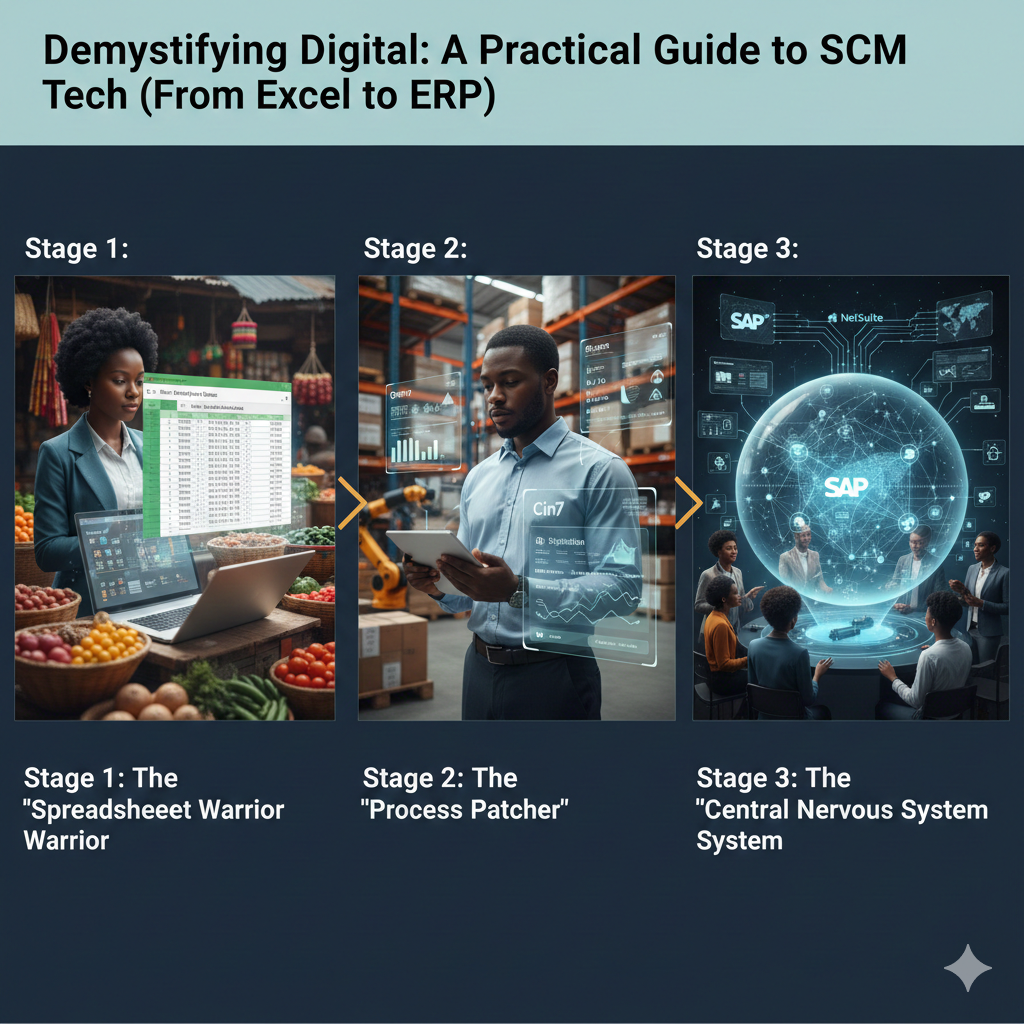

Stage 1: The "Spreadsheet Warrior"

Status: Early Stage / Startup The Tool: Microsoft Excel or Google Sheets

First, let me validate something for you: There is no shame in running your supply chain on spreadsheets.

Excel is the grandfather of supply chain management. It is cheap, infinitely flexible, and you already know how to use it. In the beginning, when you are figuring out your product-market fit, a spreadsheet is actually better than rigid software because you can change your processes on the fly.

When it works:

You have a low SKU count.

One or two people handle all purchasing and logistics.

You need to keep cash flow tight.

The Breaking Point (When to move on):

You know you’ve outgrown Excel when you encounter "The Version Control Nightmare." This is when Inventory_Final_v3_UPDATED.xlsx doesn't match what is actually in the warehouse, and you sell stock you don't have. When you spend more time fixing data entry errors than actually moving products, it’s time to graduate.

Stage 2: The "Process Patcher"

Status: Growth Mode ($2M - $10M Revenue) The Tools: Point Solutions (Inventory Apps, Shipping Aggregators)

At this stage, your volume is picking up. You can’t rely on manual data entry anymore. This is where you introduce Point Solutions—software designed to do one thing really well.

Usually, businesses in this stage need two specific fixes:

Inventory Management System (IMS): Tools like Cin7, Unleashed, or DEAR. These act as a central database for your stock. When you sell an item on Shopify, the IMS automatically deducts it. No more manual subtraction.

Shipping Aggregators: Tools like ShipStation or Shippo. Instead of logging into FedEx, then UPS, then DHL to compare rates, these tools bring all carriers into one dashboard and print labels in bulk.

Why this stage is critical: This is where you learn the most important lesson in supply chain tech: Process comes before Technology. If your physical warehouse is a mess, buying software just makes it a digital mess. You are automating your chaos. Clean up the process first, then apply the software.

Stage 3: The "Central Nervous System"

Status: Scaling / Enterprise The Tools: ERP and TMS

You are now a complex organization. You have a sales team, a finance team, a warehouse team, and a procurement team. The problem? The sales team uses Salesforce, the warehouse uses an IMS, and Finance uses QuickBooks—and none of them talk to each other.

Welcome to the era of the ERP (Enterprise Resource Planning) system.

Think of an ERP (like NetSuite, Microsoft Dynamics, or SAP) as the brain of your company. It connects every organ. When a customer places an order:

The ERP tells the warehouse to pack it.

It tells finance to send an invoice.

It tells procurement that stock is getting low and to reorder.

It does this all instantly, without a single email being sent.

At this level, you might also add a TMS (Transportation Management System) to optimize freight routes and costs dynamically.

The Reality Check: ERP implementations are expensive and difficult. They require you to map out every single business process you have. Do not jump to this stage until the pain of not having it outweighs the cost of implementing it.

The "Golden Rules" of Buying Tech

Regardless of what stage you are at, use these three rules before signing a contract for new technology:

Don't Automate a Bad Process: Technology magnifies efficiency, but it also magnifies inefficiency. If your picking process is slow, software will just help you make mistakes faster. Fix the workflow, then buy the tool.

Integration is King: If you buy a new inventory tool, ask one question first: "Does this plug directly into my accounting software and my website?" If the answer is "No, you have to upload a CSV file," run away. The goal is to eliminate manual data entry, not create new administrative tasks.

Adoption > Features: You can buy the most powerful software in the world, but if your warehouse team finds it too confusing to use, it’s worthless. User-friendly interfaces often beat "advanced features" in the real world.

The Bottom Line

Digital transformation isn't about buying the most expensive toy on the shelf. It’s about finding the right tool to solve the specific bottleneck you have today, while keeping an eye on where you want to be tomorrow.

Start with spreadsheets. Graduate to apps. Scale with ERPs. Just don't stop moving.