It’s a scenario every

business owner knows too well: a customer wants to buy a popular item, but the

shelf is empty. You check your inventory system, which confidently reports you

have plenty in stock. The customer leaves frustrated, a sale is lost, and

you’re left scrambling. This moment of "phantom inventory" is more

than a minor glitch; it’s a symptom of a deeper, systemic failure. When your

system thinks an item is in stock, it triggers a "replenishment

freeze," completely halting the reordering process. This guarantees a

long-term stockout and creates a dangerous blind spot in your supply chain.

These moments are just

the tip of the iceberg. The real issues driving lost sales and shrinking

profits are often hidden in plain sight, masked by flawed data and misplaced

priorities. Conventional wisdom about inventory management simply isn't

equipped to address the true root causes of these costly problems.

This article will uncover five of the most surprising and impactful truths about inventory management. We will move beyond the obvious culprits to reveal that the real challenges are not what they seem. By understanding these hidden realities, you can begin to protect your business from the silent profit killers eroding your bottom line.

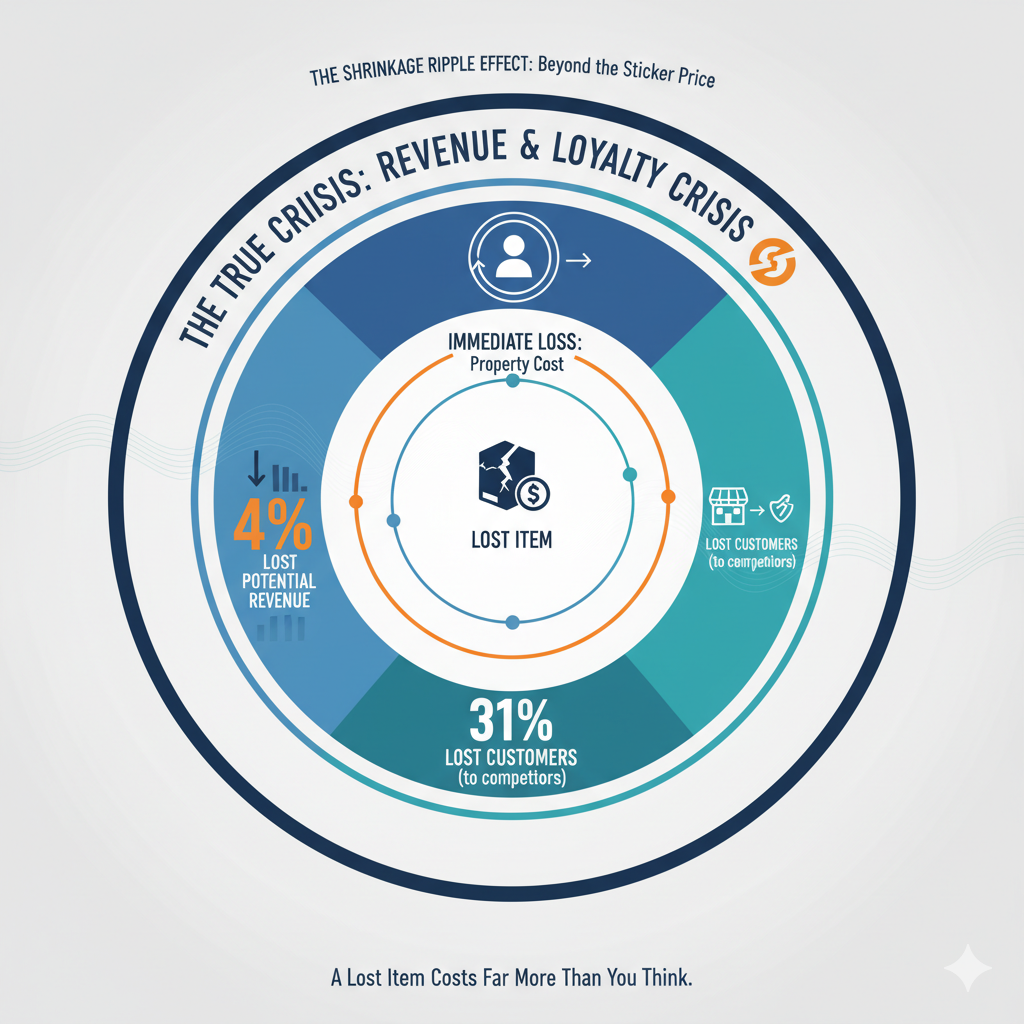

1. The Hidden Price

Tag: A Lost Item Costs Far More Than You Think

When an item

disappears from your inventory, it’s easy to calculate the loss based on its

cost. But this is a dangerous oversimplification. The counter-intuitive truth

is that the sticker price is the least of your worries. The immediate loss is

property, but the much larger, delayed loss is revenue. A single stockout

triggers a cascade of financial damage that harms your business long after the

item is gone.

The average retail

business can lose a staggering 4% of potential revenue due to out-of-stock

products. When faced with an empty shelf, customers don't always wait

patiently. In fact, 31% will choose to buy from another retailer, taking their

money and their loyalty to your competitor. The ripple effect of a single

missing item extends far beyond its value on the balance sheet.

In fact, revenue losses due to out-of-stocks can far outweigh the property losses due to the disappearing items.

This reframes "shrinkage" entirely. It is not a minor cost of goods sold problem to be written off at the end of the year. It is a direct threat to your top line, transforming into a revenue and customer retention crisis. Every lost item represents a lost opportunity to satisfy a customer, which is a cost far greater than the product itself.

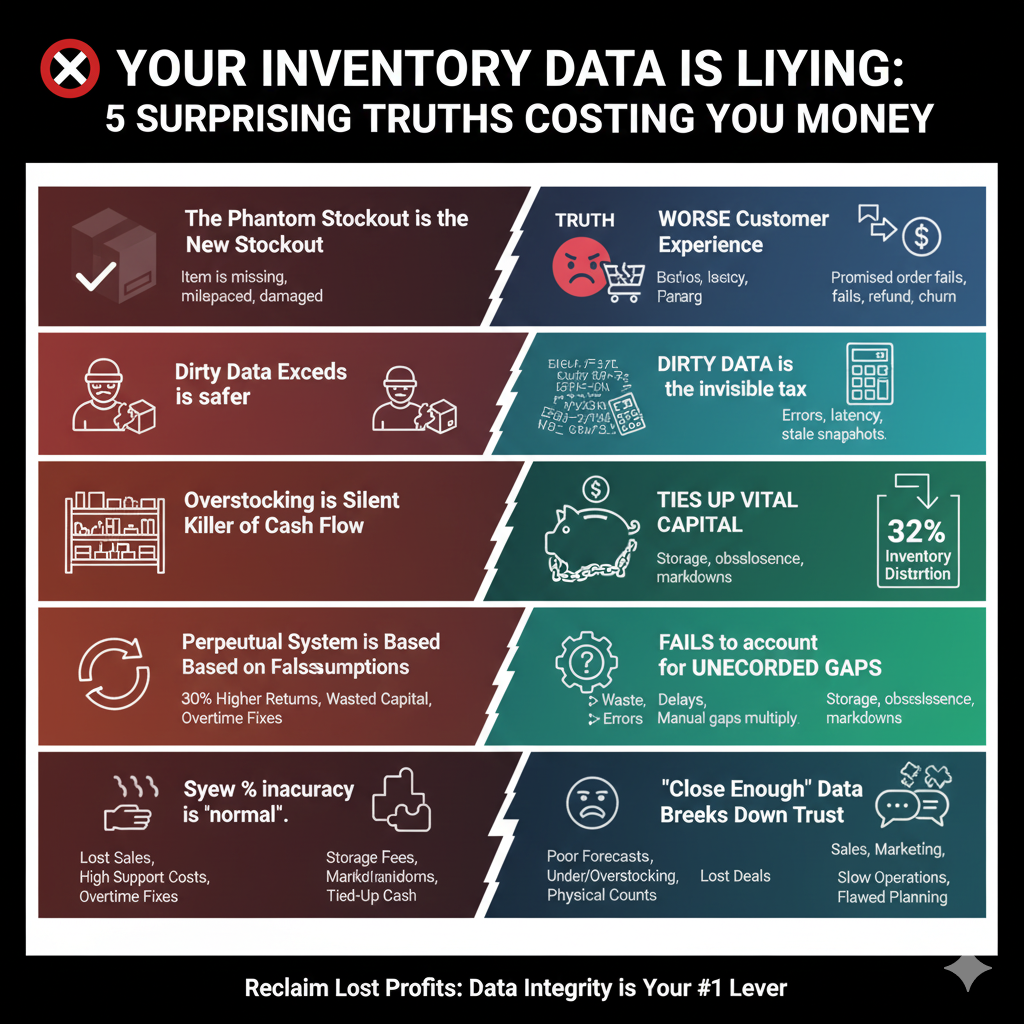

2. Your System is

Wrong: The Shocking Unreliability of Inventory Records

We invest in

sophisticated systems to give us a clear, real-time picture of our stock. The

shocking reality, however, is that these records are often dangerously

inaccurate. This foundational error directly undermines automated

replenishment, demand forecasting, and nearly every strategic decision you

make.

Imagine making

critical business decisions knowing that the data for roughly half your

products is wrong from the start. A study of "Company A," a global

retailer, revealed this was exactly the case:

- Only about half the SKUs in their stores

had perfectly accurate inventory records.

- On average, the inventory record for one

out of every four SKUs deviated from the actual physical stock by six

or more items.

These discrepancies

aren't isolated incidents; they are the result of systemic issues that corrupt

data daily. The most common causes include:

- Stock loss (shrinkage): Theft, damage, or administrative loss

that goes unrecorded.

- Transaction errors: Mistakes at checkout, where a cashier

scanning one item multiple times corrupts the data for two separate SKUs.

- Inaccessible inventory: Items that are physically in the store

but lost on the wrong shelf, rendering them invisible to both customers

and replenishment systems.

- Incorrect product identification: Mislabeled products or wrong barcodes

that throw off counts at receiving or sale.

When the foundational data is this unreliable, every decision built upon it, from automated ordering to financial planning is compromised.

3. The

"Shrinkage Iceberg": The Biggest Threats Are Invisible

Like an iceberg, the

most visible part of inventory loss is only a fraction of the total problem.

The most significant, and therefore most dangerous, portion is the massive

amount of "unknown" loss that businesses cannot see, measure, or

explain.

This concept, known as

the "Shrinkage Iceberg," highlights a critical gap in business

intelligence. Research shows that for retailers in the Fast-Moving Consumer

Goods (FMCG) sector, an estimated 59% of all stock loss is classified as

"unknown." This means that companies cannot explain where, how,

or when nearly €10 billion of stock simply disappeared.

Without doubt, a

paucity of data plays a pivotal part in producing poor product protection.

This is a crucial takeaway for any manager. You cannot solve a problem you cannot see. The enormous category of "unknown" loss is not just a rounding error; it is a critical failure in data collection, tracking, and analysis. Without understanding the root causes of the majority of your losses, any attempt to fix the problem is simply guesswork, leaving your business vulnerable to threats that remain hidden beneath the surface.

4. The Misguided

Spotlight: Focusing on the Wrong Problems and Products

Many businesses pour

enormous resources into loss prevention, but their efforts are often critically

misdirected. The reason is simple: losses don't happen everywhere; they happen

in predictable hotspots. Yet, most companies take a "peanut butter"

approach, spreading resources thinly across the entire organization instead of

concentrating them where they matter most.

Losses are highly

concentrated in what are known as "Hot Products" (a small

number of high-risk items) and "Hot Stores" (a few high-loss

locations). These hotspots typically account for a disproportionate amount of

total shrinkage. Ignoring this data leads to wildly inefficient spending. For

example, one senior retail manager admitted that tackling shoplifting accounts

for about 95% of their security budget. This is a prime example of a

misguided spotlight, as external theft constitutes only about one-third of the

company's total losses, with internal theft and process failures being other

major contributors.

This insight is transformative. It allows businesses to shift from a broad, expensive approach to a targeted, data-driven strategy. By focusing resources on the true "Hot Spots," you can achieve far better results while using fewer resources.

5. The Human

Factor: Your Team is Your Most Powerful Inventory Tool

Technology and data

are essential, but they are only part of the solution. The most critical and

often overlooked factor in successful inventory control is your team. The

effectiveness of any system ultimately depends on the people who use it every

day.

A lack of

cooperation, both within departments and between supply chain partners is a

major barrier to reducing stock loss. When teams work in silos, processes break

down and accountability disappears. Conversely, organizations that build a

culture of shared ownership see dramatic improvements. The most effective

strategies are not punitive; they focus on earning employee buy-in by

connecting loss prevention to their success and work environment.

Consider implementing

concrete strategies to foster this culture:

- Explain to employees that loss prevention

is part of a plan to create a better work environment for them.

- Implement more frequent employee

appreciation events to show they are valued.

- Offer career mentoring to

demonstrate an investment in their personal success.

When employees are

invested in the success of the business, they will be much more likely to

protect it from losses.

This perspective shifts inventory control from a purely technical problem to a leadership and cultural challenge. Investing in your team's engagement is not a "soft" skill; it is one of the most powerful levers you can pull to protect your inventory, improve accuracy, and drive profitability.

Conclusion: From

Fighting Fires to Building a Resilient System

The five truths we've explored demand a fundamental strategic shift. The goal is not to get better at fighting the visible symptoms of inventory problemsempty shelves, known theft, accounting write offs but to re-architect the system's foundation. This means moving from a reactive posture to building a resilient operation based on data integrity, surgically focused efforts, and a deeply ingrained team culture of ownership. Challenging old assumptions is the first step toward reclaiming lost profits and building a more robust business.

To start this process,

ask yourself one powerful question:

Given that your

inventory data might be wrong and your biggest losses are likely invisible,

what is the one process you will re-examine first to protect your bottom line?